Here’s the approximately annual giant video update:

If you’re interested in any of the topics in more detail, I’ve collected links to individual posts for each of the referenced items below.

Thanks for all your support in the last year!

Moteus

Announcement of moteus r4.3: Production moteus controllers are here!

Automated programming and test setup: Programming and testing moteus controllers

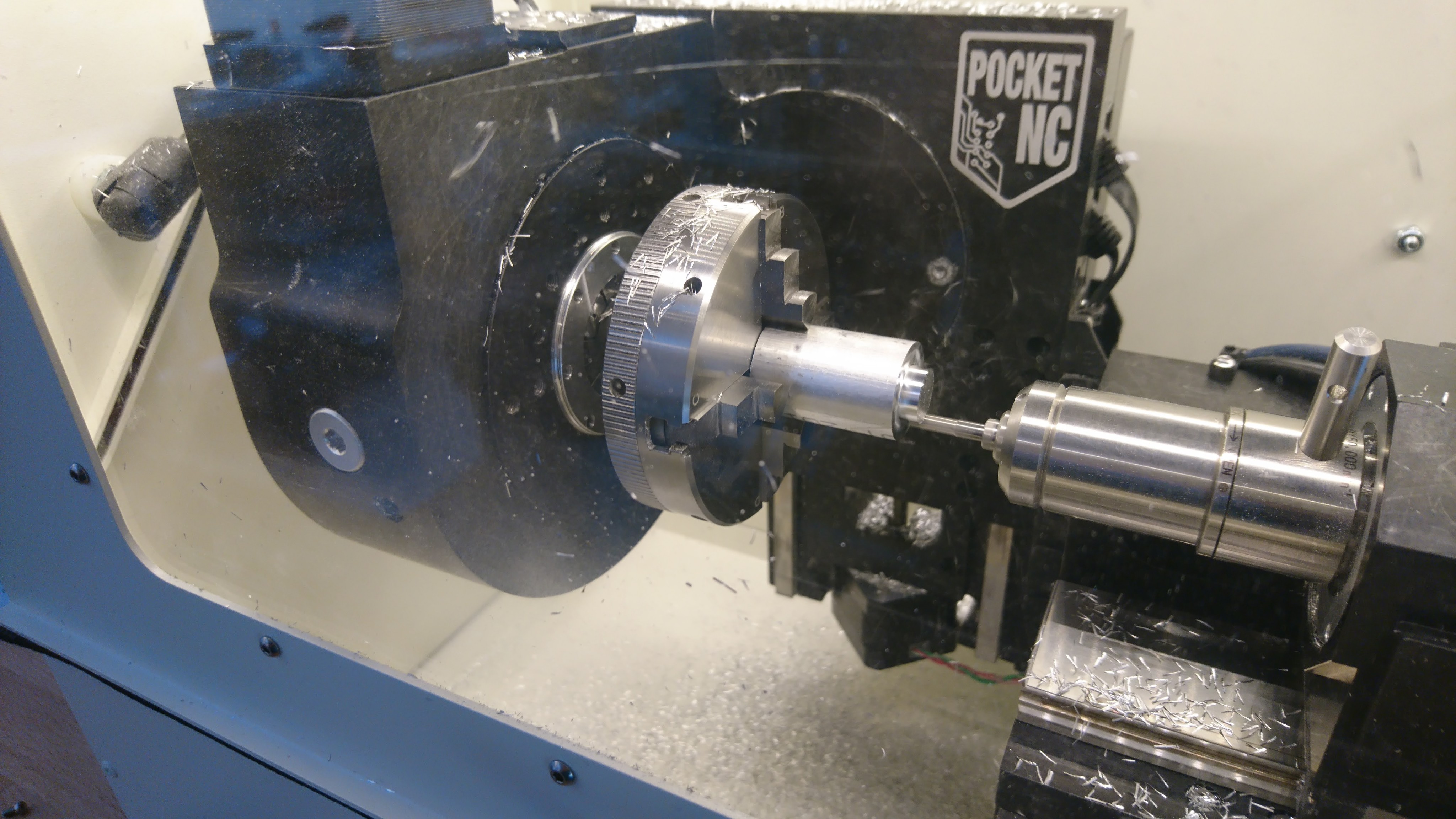

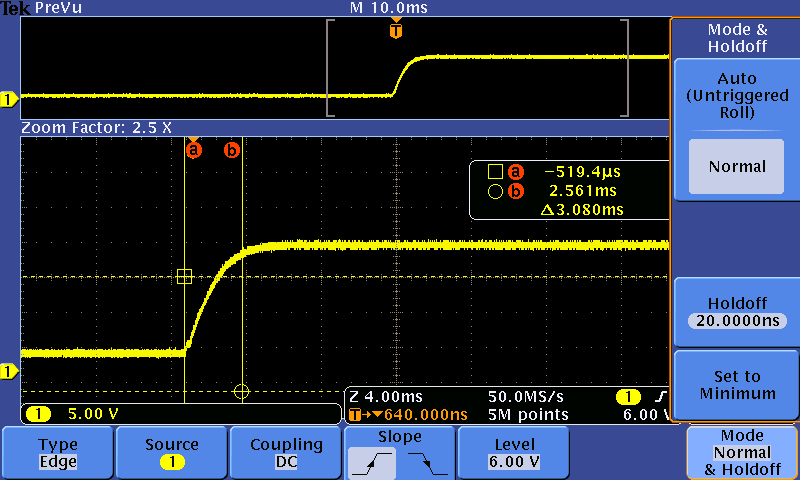

Dynamometer: Measuring torque ripple, Initial dynamometer assembly

Continuous rotation: Unlimited rotations for moteus

The virtual wall control mode: New “stay within” control mode for moteus

Handling magnetic saturation: Dealing with stator magnetic saturation

qdd100

Discussion of the overall design, and details on individual sub-components:

- moteus servo mk2

- moteus servo mk2: Planet Input

- moteus servo mk2: Outer housing

- moteus servo mk2: Front housing

- moteus servo mk2: Back housing

- moteus servo mk2: Functional test

- Making the reduced weight servo mk2

- moteus servo mk2: Reduced weight test

And the pre-production mk2 servos: Pre-production mk2 servos

Accessories

fdcanusb: Introduction and bringing it up

power_dist: The failed r2, the closer to working r3, and the final r3.1

pi3hat: Initial announcement, bringing it up, and measuring its performance

Demonstrations

Ground truth torque testing: Ground truth torque testing for the qdd100

Skyentific’s telepresence clone: qdd100 telepresence demo

kp and kd tuning: Spring and damping constants

quad A1 – Hardware

Lower leg updates:

- The first quad A1 leg: Update leg design for mk2 servo

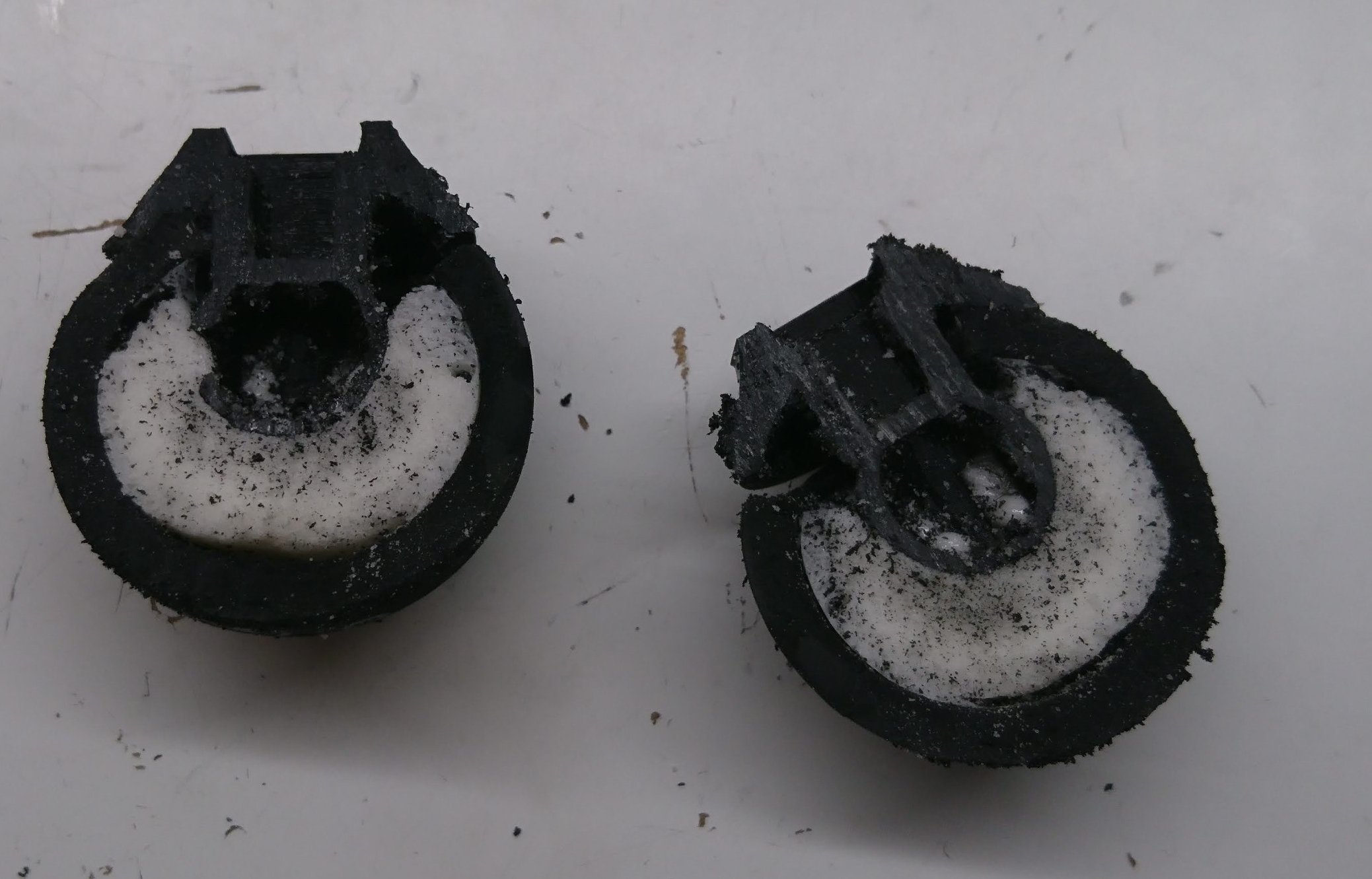

- The first foam cast foot: quad A0 – Improved foot design

- Longer and with a knee gear reduction: quad A1 leg updates

- A fixture to assemble legs: Quad feet construction fixture

- One of the feet failures: Another foot failure

Chassis: The first introduction, and some minor tweaks

Cable conduit changes: New leg cable management

quad A1 – Software

Cartesian coordinate control: Cartesian leg PD controller

Pronking: Successful pronking!

tplot2 and its sub-pieces:

- Updated serialization library

- Revised mjlib serialization design

- C++ serialization API

- Log file format

- tplot2

- Video in tplot2

- 3D rendering in tplot

- Video and telemetry synchronization

Simulation: Resurrected quadruped simulator

nrf24l01 transceiver and its sub-components

- Spread spectrum RF control and telemetry

- Spread spectrum protocol design

- Spread spectrum implementation

- Spread spectrum integration

Smooth leg motion: Improved swing trajectory

Balancing

- Primitive gait balancing – 1D

- Balancing gait in 2D

- Balancing on estimated terrain

- Testing real-life hill operation

All four feet off the ground: Higher speed gait formulation, and Stable gait sequencing

Improved stand up sequence: quad A1 stand-up sequence part N

Speed records:

- 0.5 m/s: Balancing gait in 2D

- 1.7 m/s: First look at higher speed gaits

- 2.0 m/s: Another speed record: 2 m/s

- 2.5 m/s: Another quad A1 speed record – 2.5 m/s