Previously, I described the overall plan for my improved foot. To make that work, I needed to cast a 3d printed part into the squash ball such that it would likely stay attached during operation, be suitable rigid and yet damped, and do so repeatably.

To start with, I used a random single yellow dot squash ball with a hole cut in one side using a pair of side cutters. For the casting foam, I just used Smooth-On Flex Foam-IT 17, which is what Ben Katz originally used at least. Initially I just mixed up a batch, poured it in to a random level, stuck my bracket in and hoped for the best.

Well, something sure happened! But not exactly what I wanted. The foam didn’t fill in the interior cavity, nor make a great connection overall with the bracket. On top of that, the process wouldn’t exactly be described as “repeatable”. Since I just eyeballed the level of foam, there was no way to get the same amount in.

For my next runs, I decided to do everything by weight. I tried a few different foam masses, curing orientations, and venting strategies. Eventually, I got something that seems to look pretty good. We’ll see how well it works on the actual machine shortly!

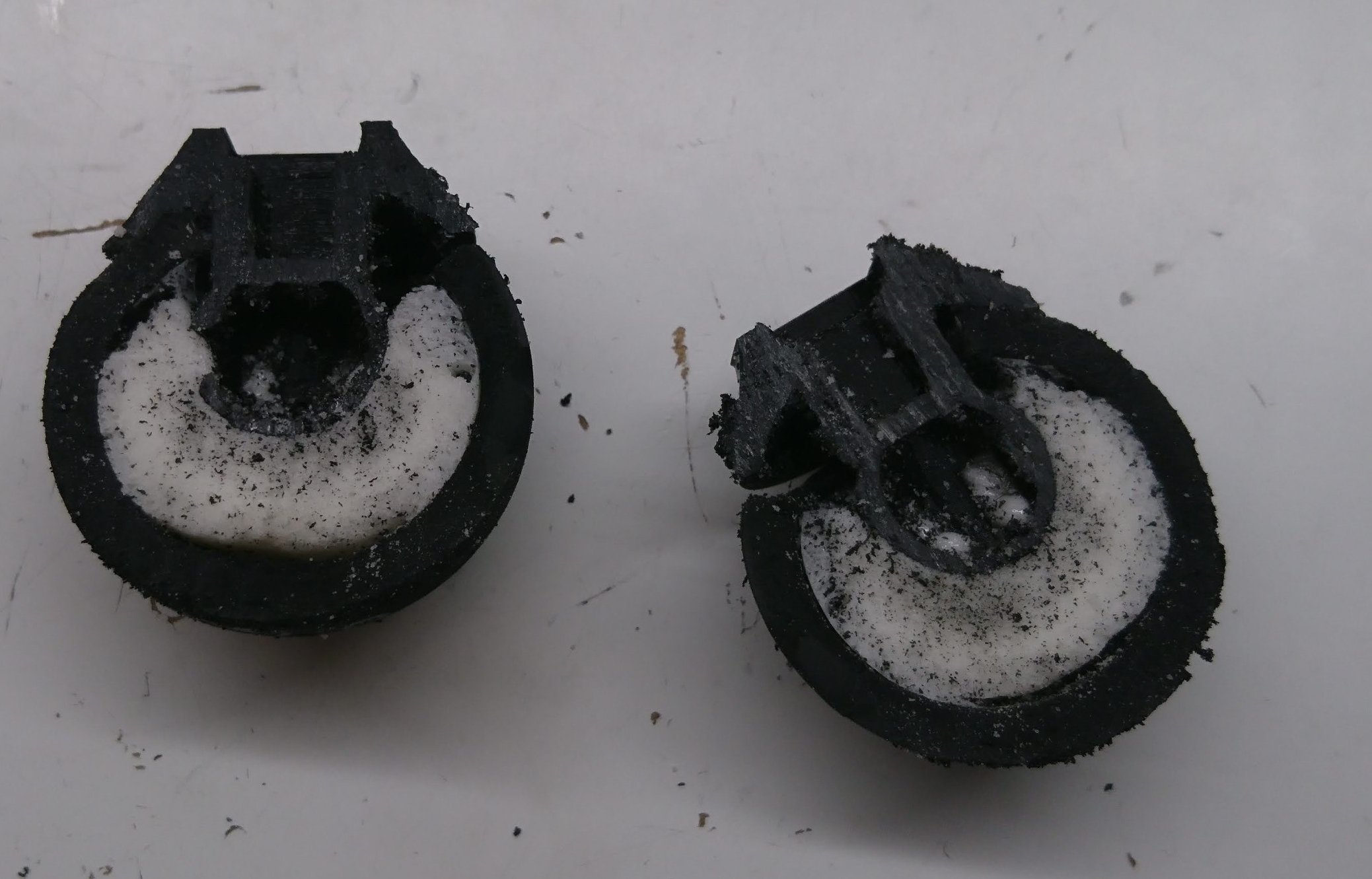

Here’s a bunch of different intermediate attempts:

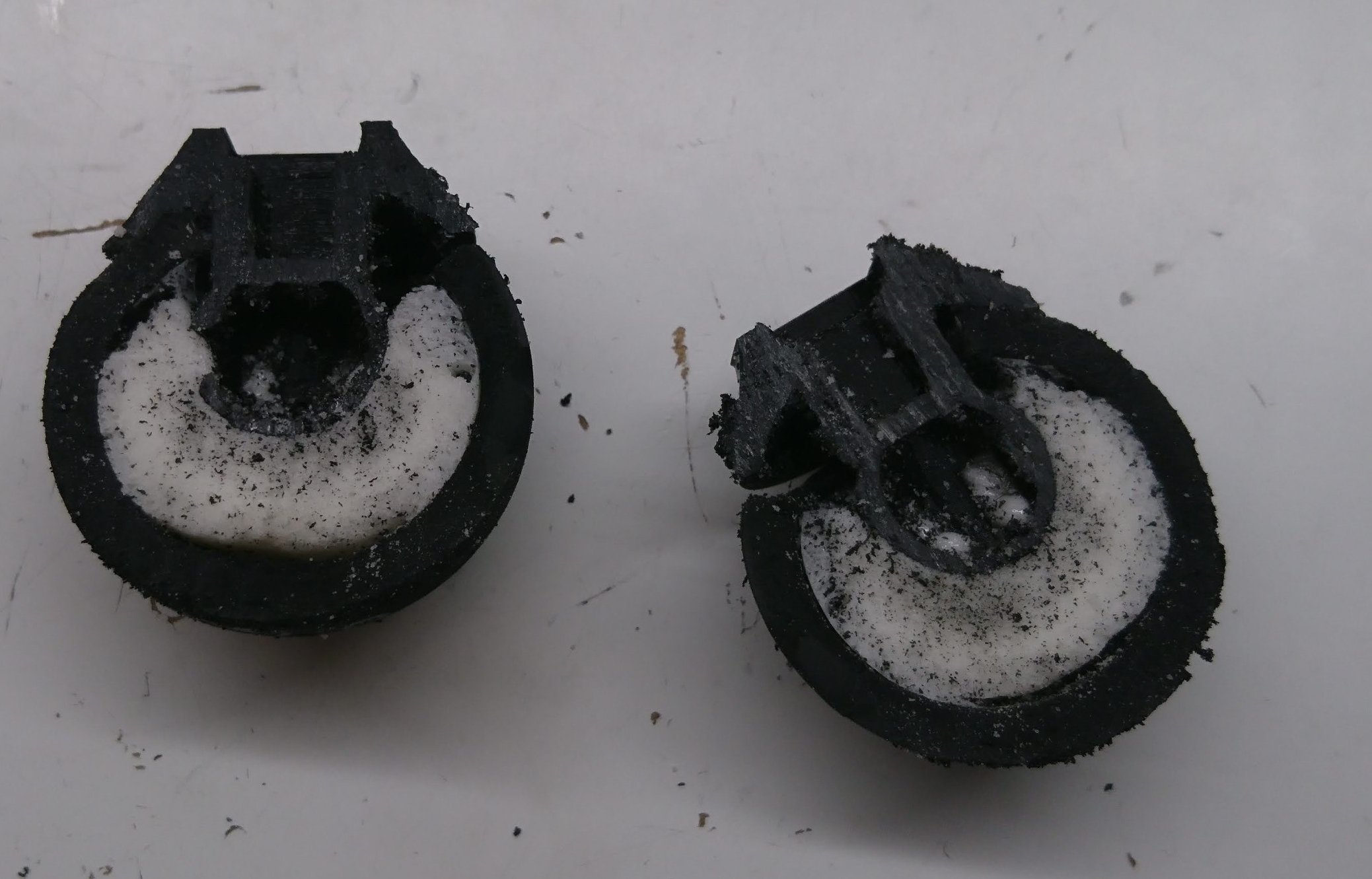

And here’s a cutaway of the process I’ve settled on for now. This particular one has a slight bit of overfill on one edge that is more than is typical, but the inside fill is pretty good: