If you look around online, there are lots of examples of PCB test fixtures used to perform end of line testing. In the low to medium volume scale, nearly all of these are either clamshell or 2 side affairs, where probe pogo pins or interfaces are connected to the bottom and top of the board.

When developing the moteus-n1, one of the challenges was the number of right angle board edge connectors it has. Those right angle connectors are what allow it to maintain a very low overall stack height when installed in applications, but are also much harder to perform testing on, since by definition the access points are not vertical. On the base n1, there are 6 total right angle connectors, 2 on each of 3 sides, and future variants may have additional bottom side CAN and power connectors populated to make 8 total right angle connectors.

In very low volume testing, say less than a hundred a day, it is feasible to just have a human manually connect cables to each of the connectors for each board being tested. As the volumes scale up though, this becomes a big bottleneck, and if the testing is not performed in a low-wage country, it can amount to a measurable portion of the overall product cost.

Design Overview

Thus, meet the test fixture I built for the moteus-n1:

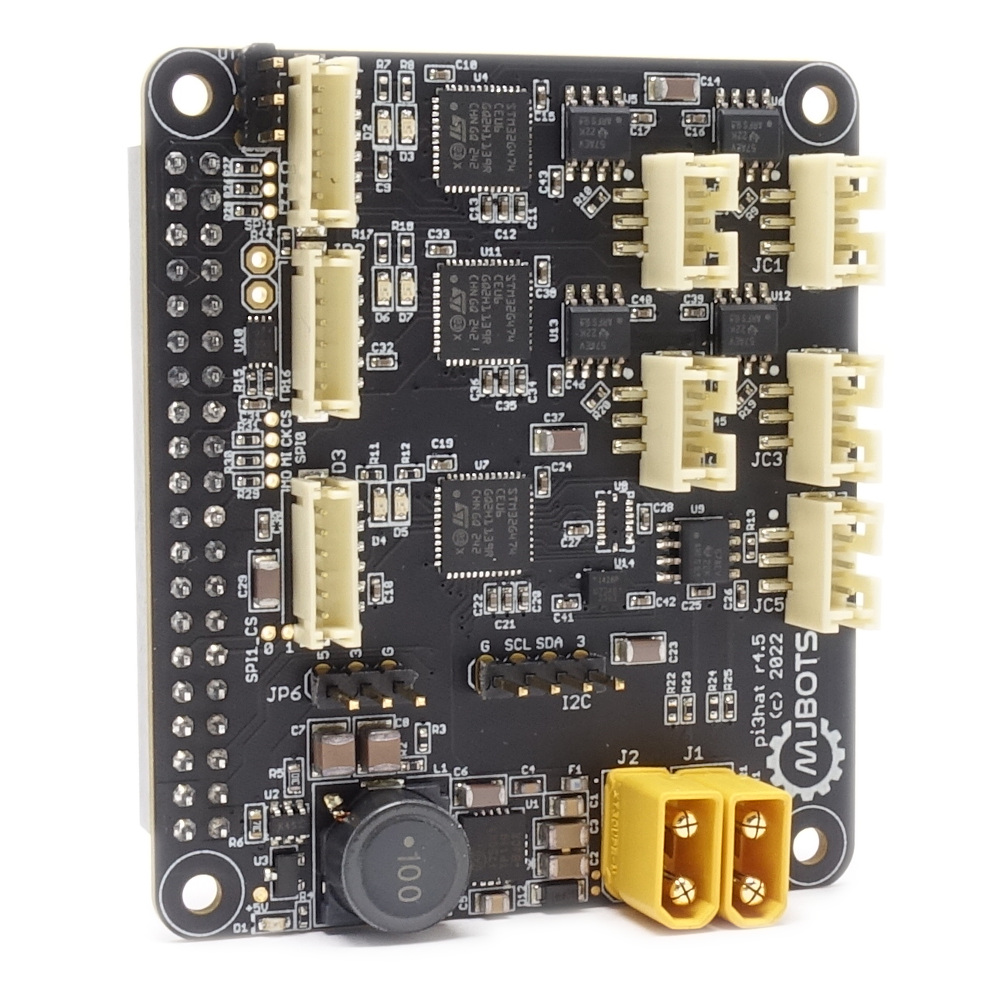

It is manually actuated with a single big lever. As you pull the lever down, a series of guideways cause first the top plate to clamp the board into position vertically, and then subsequently three side plates slide in horizontally to attach probe points to three of the side edges. It is mounted in an 2020 extrusion frame that also hosts a 24V power supply, a Raspberry Pi and mjbots pi3hat, a lightly modified mjbots power_dist, and a custom STM32 nucleo I/O expander board.

I can’t say that the mechanics of the system are particularly elegant, but they work. When I started on the project some time ago, I went looking through a bunch of mechanisms to try and find something simple that could sequence the motions I wanted. I got pointed to thang010146’s youtube channel (for which you can get everything offline too) which is an amazing repository of ideas! However, after looking at a large fraction of those, and other resources to boot, the best I had come up with was a cam-like system where bearings were made to slide through pathways with a controlled profile. The profile can then be tailored to create arbitrary motion profiles for each of the driven pieces.

For instance, the vertical aspect looks like this in the closed position:

The guideway in the “closed” region forms an arc centered on the center of rotation of the handle, this keeps the top plate stationary. Then there is a region where the top plate is lifted, and finally a region at the end which is once again an arc about the center of rotation when the top plate is at its maximum extent. Thus, when the handle is pulled, the top plate initially remains level, drops down, and for the last N degrees of handle rotation, remains fixed at its lowest point.

The side plate that engages from the rear of the board is constructed nearly identically, with a guideway on the same face of the handle. The two plates that come from the left and right use a similar guideway, but here the guideway is in the curved section of the handle, which was harder to model in CAD.

This view from the back shows that the guideway for the left and right rails runs straight during the bulk of the handle pull, and then near the end pushes the side probes in towards the board. 3D printing this geometry was challenging, and I ended up printing a closed channel, and then post-processing it to remove a thin wall after printing was complete.

For the probes, each of the 5 sides has a removable probe plate which can be easily swapped out or changed. Most of the probes use the same modular test pogo pins that the most recent r4.11 test fixture used. Most of these pogo pin receptacles used the same installation approach that the previous fixture used, in that the holes for them were directly 3D printed. However, for the 1.5mm pitch JST ZH pins, PA50 size probes were required, and I could not get my prusa to reliably print usable hole sizes. So instead I had it print a tiny registration hole, and then used a $15 micro-PCB hand drill in two stages. First at 0.8mm all the way through, then at 0.9mm halfway through.

This allowed the receptacles to be pressed in reliably with a small arbor press:

This worked well for all the things that could be pogo-pinned, however the JST GH connectors are not amenable to be probed with any of the standard probe shapes. For those, I instead hand whittled mating GH connectors by removing the locking latch and shaping the remaining plastic to help them mate from a wider range of angles and offsets. Then I hot-glued them into place into the removable probe plate. I will admit they were finicky to get working well. The probe plate got re-printed a few times to line things up well, and the hand-whittling was an iterative process until I could get the connectors to reliably mate into the board.

Like in the previous fixture, a mj5208 motor is installed in the bottom, to provide a way to test the magnetic encoder and to test the power stage of the driver.

The I/O expander is an STM32 Nucleo board mounted into a simple custom PCB. It has a bunch of 0.1″ pin header connectors for all the probes to connect to, and routes all the things that need to be sensed with ADCs to resistor dividers, all the GPIOs to appropriate pins on the nucleo, and anything that is tested with an external device like the RS422 transceiver to yet other connectors. I populated it by hand, and included a 0 ohm resistor on nearly every line so that I could easily disconnect things that didn’t work, which ended up being necessary when I made some mistakes in pin assignment.

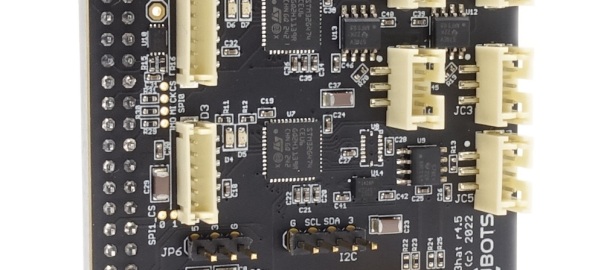

The Raspberry Pi 4 that runs the software has a mjbots pi3hat attached. That powers the rpi from the 24V input and also is used for a CAN connection to the power_dist board. A quick 3D printed mount holds it together and lets it clip onto the frame.

A hall sensor is mounted on the spring clip, so that the test application can automatically start the test cycle when the handle is fully closed.

Operation and Software

The software used is a derivative of the software used for the previous test fixture. First, it was updated to use the I/O expander board to take all the new measurements, such as verifying that all the ground and power pins on each connector are working properly, as well as all the additional GPIOs. Second, and more obvious, is that it was updated to use the python textual library to create a two-paned application.

One pane shows the ongoing results of the current board being tested, and the other pane shows the previous board’s results. The script was also updated to play an audible sound when a board is ready to be removed, so that uploading results from the previous board can take place in parallel with the beginning of the next test cycle.

Conclusions and Future Work

With this fixture, it is possible to reliably test and package more than 70 boards an hour, including all the additional test coverage. That is up from around 30-40 boards per hour with the old fixture. While the r4.11 has less need for side probing, it is still possible that a fixture based on this designed for it will be made at some point, if nothing else to add verification of the ABS port and the improved test cycle time.