My last video gave an overview of what I’ve accomplished over the past year. Now, let me talk about what I’m planning to work on going forward:

I intend to divide my efforts into two parallel tracks. The first is to demonstrate increased capabilities and continue learning with the existing quad A0, and second is to design and manufacture the next revision of all its major components.

New capabilities and learning

The first, and most important capability I want to develop is an improved gait and locomotion system. While the moteus servos in the quad A0 are capable of high rate compliant control, the gait engine that I’m using now is still basically the same one that I made for the HerkuleX servos 5 years ago. It just commands open loop positions to each of the servos and uses no feedback from the platform at all. This severely limits what the robot can do. For instance, if the terrain is not level, legs will drag on the ground or it will not walk at all. The maximum speed is relatively slow and achieving it requires careful tuning of servo-level gains. While it is more robust than nearly any other open loop 4 legged walker while standing up, even small disturbances can cause it to fall over.

At a minimum, I’d like to switch to controlling the position and force of the endpoint of each leg and switch to a gait engine that takes into account the actual position of each joint during the gait cycle. That should enable it to maintain good ground contact with all feet that are intended to be in a stance position. Now, often feet will skip around, as the servo gains are all relatively high to account for the lack of feedback.

The next level would be to take into account an IMU to ensure balanced feet lift offs. While I have an IMU in this configuration, it currently isn’t usable due to my improvised attempts to improve the overall system update rate. I’ll need to update some of the hardware to get an IMU again before I work on this part.

New hardware revisions

I have learned a lot with the moteus controller, servo, and the quad A0 over the last year. I’d like to take that learning and update the components to achieve:

- Manufacturability: Many of the sub components now are very labor intensive to produce or assemble.

- Cost: I have in many cases made things much more expensive than they needed to be in order to shave a bit of time off the prototyping process. Also, I have enough confidence now to get larger volumes of parts, which further reduces cost.

- Capability: There are many easy areas where the system performance can be greatly improved.

My overall goals are to make a system that is capable and affordable — to provide an ecosystem of parts and systems for researchers and hobbyists to use. That means keeping everything open source, and providing access to all subcomponents and designs while still being able to provide a complete system that is capable out of the box.

Here’s a quick rundown of the various areas I’m tackling:

Moteus controller

My next revision of this controller will be a slightly bigger change, in that the form factor, the microcontroller, and the connectors used will all be altered. I’m planning on switching to an STM32G4 for the controller, using daisy-chained connectors for power in addition to communications, switching to FD-CAN for communications, and reworking the form factor to enable all the primary connectors to exit from one edge of the servo.

Also, I’ll take this opportunity to design for automated end of line test. That means I will leave enough probe points such that a test fixture can validate the correct operation of a board without intervention.

I don’t anticipate the performance to change a whole lot, although I may increase the allowed input voltage. Even so this will still be a very capable board, with 3 phase current sensing, >=50A peak phase current, >= 400W peak power and a switching and internal control loop rate of >=40kHz.

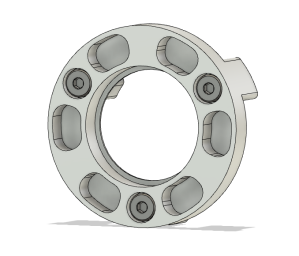

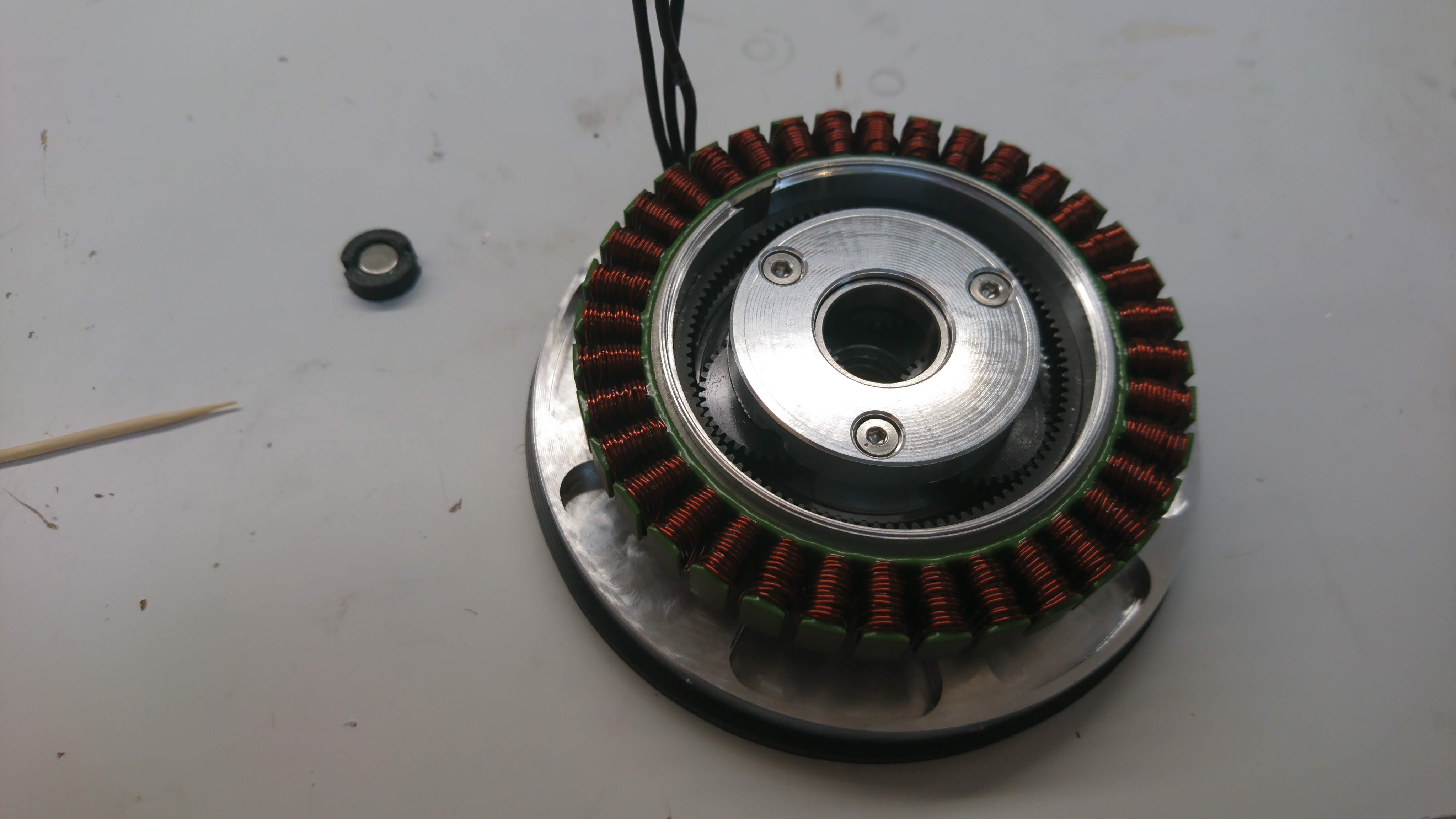

Moteus servo

The first round of gearbox servos went through many revisions to achieve something that was functional. That said, while functional, they are fragile, and require about a full man day of assembly time per servo. I’m working to get pre-production volumes of around 100 units for all the components such that no post machining will be required and the servos can just be assembled together.

While I’m at it, I intend on switching everything to metal from 3d printed plastic, and reducing the overall dimensions. It is likely the mass will increase a little from the current 410g, but I’m hoping that it won’t be that much compared to the increased strength and rigidity.

Junction board / raspberry pi 3 hat / pre-charge board

I intend to rework the architecture behind the power and data distribution internal to the quad A0. Currently there is a raspberry pi3 hat, which merely powers the raspberry pi and provides an RS485 interface. Then a “junction board” splits out the RS485 bus into four separate connectors as well as splitting out power to all four legs and housing the IMU. Finally, a separate “pre-charge” board ensured that the servos can have power applied safely.

I intend on moving all data distribution and the IMU onto the board that mounts on the host computer. Thus it will have power in, an IMU, and 4 (or maybe more) CAN bus outputs. Then, a separate power distribution board will include the pre-charge circuit as well as connectors for power for all four legs. Simultaneously, I plan on adding an actual power switch, so that I don’t have to keep pulling the battery in and out to cut power.

Chassis

The quad A0 chassis is a single monolithic 3D printed block. Actually attaching legs to this is nigh impossible. It takes a long time, and not all of the joining screws can actually be used because of interference with other pieces. Also, using the Ryobi style batteries results in a lot of dead space due to the mounting stud. I am planning on switching this chassis to be printed in multiple components that are assembled together with screws and threaded inserts and switch to a battery form factor that is more compact.

That should also allow for mounting the primary computer inside the chassis, and still leave enough room for a bigger computer, like an NVIDIA Jetson nano.

Legs

I’ve already had one failure in the current iteration of the leg that indicates some redesign is necessary. Also, the two primary brackets that connect the shoulder to the upper leg, and upper leg to lower leg should be made from aluminum instead of being 3d printed. Those brackets had to be really big and printed in odd orientations in order to be strong enough, and they could be a lot lighter, more convenient, and more cost effective in metal.

Looking forward

Thanks for all of your positive feedback so far, and I look forward to more exciting times executing these plans!