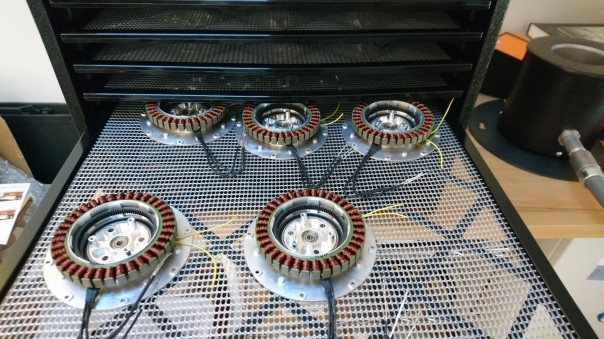

First, a limited number of qdd100 servos are available for sale to beta testers! Check them out at mjbots.com.

After building up the first set of qdd100 servos, I wanted to empirically measure their performance parameters. Some astute commenters uncovered in my terrible juggling video, that I didn’t actually have any ground truth measure of torque with these actuators. Given that the ultimate torque is a pretty useful performance metric, it’s a good thing to have a solid understanding of.

To measure this, I built a simple test fixture (which is also the qdd100 beta development kit), consisting of two brackets. The first lets the servo be bolted to a table, and the second mounts to the output and has set screws to hold a 1″ diameter pipe. I used this to insert a 1 meter pipe which then can press against a digital scale.

Then I created a simple C++ application which emitted torque commands in response to joystick input and reported back telemetry from the servo: qdd100_test

Using these I was able to generate a plot of actual torque vs motor phase current:

There are a couple of interesting things here, one is that the torque constant at low phase currents is slightly lower than I had estimated based on the motor’s Kv rating. Second, the torque constant drops off faster at higher currents than I had anticipated, and third, the motor Kv rating was lower than I had predicted. Those things combined result in a peak torque of between 12.5 and 15Nm depending upon the servo. That’s still enough torque to do some serious jumping, but exploring those discrepancies is now on my backlog.

Here’s a video showing how this testing (and max speed testing) was done: