Savage Solder: Transmission Backlash and Pavement Results

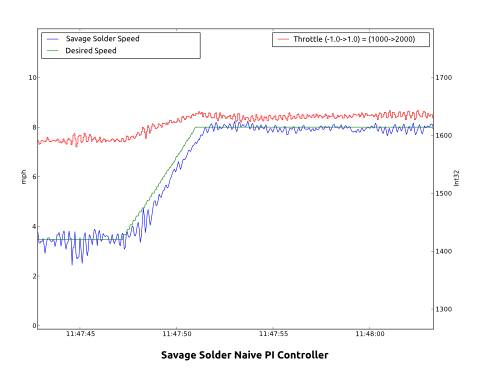

In part 1 and part 2 I looked at our progress in improving the acceleration performance of our Savage Solder autonomous racing car as applied to RoboMagellan type competitions. We left off with a reliable open loop model of acceleration versus current speed and throttle input, which were combined with some feedback elements to make a simple controller. However, upon running the controller the first time, we saw some odd behavior when the throttle transitioned to and from braking. It was difficult to see at our standard sampling rate of 20Hz, so we increased our overall control loop to 50Hz (the rate at which the RC servos are updated) to get a better view. The behavior can be seen on the plot below:

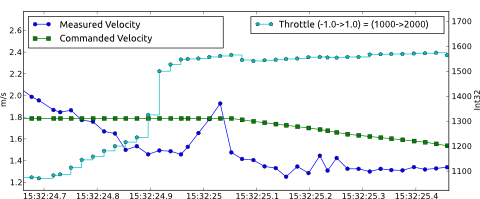

Around time 15:32:24.9, the throttle command switches from a braking command to a positive acceleration. Then just before 25.0, the velocity starts a rapid ramp up for 4 time samples, starting from about 1.4 m/s and peaking at about 2.0 m/s, a 40% increase. After those 4 samples, it snaps back into place at around the previous value of 1.4 m/s. This type of velocity spike occurs on nearly every transition between accelerating and braking.

What is happening here is caused by the backlash in the car’s transmission. There is a region of about 3-4cm where you can move the drive wheels without turning the motor caused by the aggregated slop in all the individual linkages between the motor and the drive wheel. The car is not actually speeding up or slowing down during this event, but the motor (where our velocity data comes from) does. It speeds up until all the backlash is consumed, at which point it then resumes traveling at the exact same speed as the rest of the car. This was confirmed by looking at auxiliary inertial measurement data which indicated that the car itself did not accelerate or decelerate during these events.

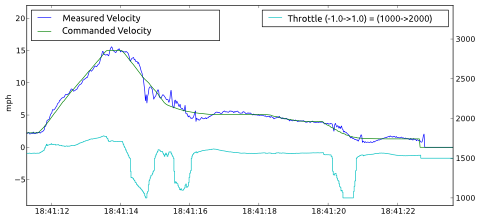

Once suitable filtering was in place to mitigate the effects of backlash, our velocity control is performing admirably on pavement test surfaces. Below is a plot of a demonstration run with a top speed of 15 mph, an acceleration of 3.0 m/s^2, and still decelerating in a controlled manner to bump a cone. With our current tuning, it starts decelerating about 8s before contacting the cone. We were just able to get enough space in our test area to get it to hold 15mph briefly. Note the accurate velocity tracking both during hard acceleration and deceleration, as well as the smooth approach into the final bumping speed.

And finally, video we took of the car when the above data was recorded:

First, a little background. The motor controller on Savage Solder is the stock

First, a little background. The motor controller on Savage Solder is the stock

For the last 6 years I have ever so slowly been learning how to fly medium sized RC helicopters outdoors, in an attempt to become a good enough pilot that I could roboticize one. About a year ago I upgraded to a Blade 450, which let me practice outdoors in a much wider variety of weather conditions and provided for a feasible amount of payload. My proficiency is now good enough that I’ve started work on the control and navigation design with the medium term goal of entering it in autonomous racing competitions, such as

For the last 6 years I have ever so slowly been learning how to fly medium sized RC helicopters outdoors, in an attempt to become a good enough pilot that I could roboticize one. About a year ago I upgraded to a Blade 450, which let me practice outdoors in a much wider variety of weather conditions and provided for a feasible amount of payload. My proficiency is now good enough that I’ve started work on the control and navigation design with the medium term goal of entering it in autonomous racing competitions, such as