Savage Solder: Staying on the pavement part 1

The Robogames 2012 event venue in San Mateo

As we gear towards higher speeds with our robomagellan entry, Savage Solder, one of the harder challenges is managing the terrain that the car drives on. In general, robomagellan competitions are held in campus or park like environments that consist of a mix of grass, pavement, wooded areas, and buildings. All of these terrain features affect how the car can navigate, and at what speeds. For instance, it shouldn’t drive into trees or buildings. In grass, the maximum speed should generally be lower than on pavement. Transition points may need an even lower speed as there could be a large bump where an area of grass ends, or where a manhole or other negative obstacle is present. Last year, we ran the car at about a maximum of 5mph, at which speed our platform can handle most all of the common event terrain features. However, as we go faster, we will want to make sure that if possible, the car stays on pavement, and avoids areas that could cause large problems.

We broke down our approach to tackle this problem into a number of discrete stages:

- **Online Replanning:**First, the car will run a local A* planner over short distances in the future. Initially, this will just avoid unexpected cones, since we are already tracking all cones in the vicinity of the car.

- Oracular Terrain:Next, we will hand annotate a map of one of our simulated environments, and create a synthetic “sensor” which reports the exact maximum speed in the robot’s local coordinate frame. This will feed into the local planner to keep the car on the path and at an appropriate speed.

- Derive Terrain from Camera:In the final stage, we will use our camera data to estimate what the maximum speed of visible terrain elements are, likely by using a simple color classifier.

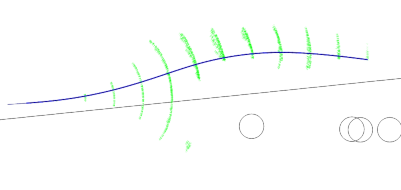

We have implemented a rough prototype of the local replanner and have had success both in simulation and in the field with it. It operates as a hybrid A* planner with a primary state space consisting of x, y, heading, and velocity. The auxiliary, non-searched, states are just the previous steering command. At each time step, the planner searches a range of steering angle adjustments, as the steering servo on our platform requires about 1.5s to move from lock to lock. In a given plan time step only a small fraction of that motion is possible. The cost metric incorporates the rate at which the steering is changed, the distance away from the global waypoint path, and the proximity to any nearby cones.

Savage Solder online replanner

In the picture above, the green vectors show the different possible vehicle positions and orientations that were considered, the black line shows the global waypoint path, and the blue line shows the best path explored so far. Each of the circles is an estimated cone (in this case there was actually only one cone, but the estimator hallucinated a few more in the vicinity).

Next, on this front, I’ll look into our efforts with an oracular terrain sensor.